The custom apparel market is experiencing unprecedented growth, with industry projections showing expansion to $132.3 billion globally by 2035 at a 13.1% compound annual growth rate. This explosive growth is driven by increasing demand for personalized fashion, corporate branding, and custom merchandise. However, with this opportunity comes a critical decision: choosing the right decoration method for your projects. DTF printing, screen printing, and embroidery each offer distinct advantages and limitations that can significantly impact your project's success, cost-effectiveness, and final quality. Understanding these differences is essential for making informed decisions that align with your business goals, budget constraints, and quality expectations. tech4a22

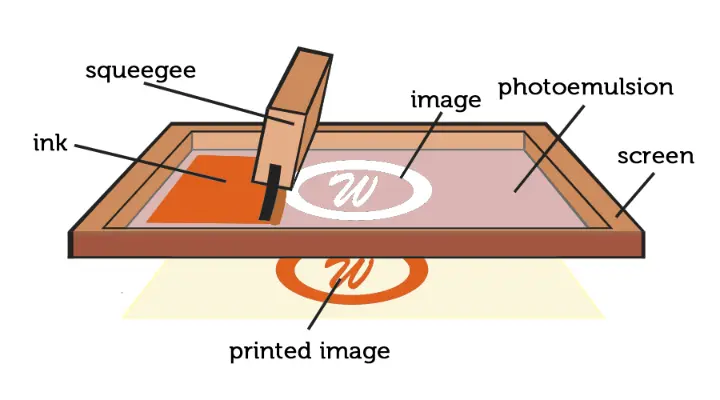

Screen Print

Understanding DTF (Direct-to-Film) Printing

Direct-to-Film (DTF) printing represents one of the newest innovations in custom apparel decoration, revolutionizing how designs are transferred to fabrics. This digital printing method involves printing designs directly onto a specialized clear film using DTF-compatible inks, then applying adhesive powder and using heat to transfer the design onto garments.garmentprinting

DTF Method

The DTF Printing Process

The DTF process consists of several carefully orchestrated steps that ensure optimal results. First, designs are prepared digitally and printed onto DTF film using specialized printers equipped with CMYK color inks plus white ink for opacity on dark fabrics. After printing, adhesive powder is evenly distributed over the wet ink, with excess powder removed through shaking. The film then undergoes curing at specific temperatures to melt the adhesive powder, creating a ready-to-use transfer. Finally, the transfer is applied to the garment using a heat press at precise temperature and pressure settings. xtool